Final (Maxed) Designs

Forum rules

Circuit-free solutions of basic factory-design to achieve optimal item-throughput

-

vanatteveldt

- Filter Inserter

- Posts: 947

- Joined: Wed Nov 25, 2015 11:44 am

- Contact:

Re: Final (Maxed) Designs

A right, sorry.

But you are arguing that *if* you use prod modules you should add speed beacons, right? I would think that the most energy efficient setup would steer away from prod modules altogether? Maybe if you also factor in the energy cost of resources (mines+smelters) with or without modules in that case.

I guess a good testcase would be total energy required to create 1 blue belt of green circuits, either with all efficiency modules or with all prod+sp modules?

But you are arguing that *if* you use prod modules you should add speed beacons, right? I would think that the most energy efficient setup would steer away from prod modules altogether? Maybe if you also factor in the energy cost of resources (mines+smelters) with or without modules in that case.

I guess a good testcase would be total energy required to create 1 blue belt of green circuits, either with all efficiency modules or with all prod+sp modules?

Re: Final (Maxed) Designs

I think there is room for module/beacon layouts here, but I would want at least some effort placed on sizing inputs and outputs correctly. For refineries and liquid only chem plants this is a non-issue, but for many of the beacon layouts referenced, where a production building has 16 speed module 4s beaconed on it, 1 or 2 fast inserters to belt will not keep up with production. As an example, a plastic chem plant within range of only 4 beacons will produce plastic at a rate of 8+ units/sec. Getting these 8 units out per sec is a problem and only 5 of these buildings are required for a full blue belt.

Re: Final (Maxed) Designs

There are two ways obviously:

1) product modules + speed modules in beacons

2) efficiency modules

and no other way. One can use a combination 3 efficiency + 1 speed at assembly machine since you are limited by 20% in energy consumption.

I think that your whole factory should have some parts oriented to first way and some parts to the second. If you try to decide between them, you should follow this factors for each process

A) If the energy consumption is too high (in comparison with other processes), its argument for the second way (efficiency modules).

B) If the energy consumption of precedents processes is too high, its argument for the first way.

C) If there is some valuable and hardly getable source at precedents, its argument for the first way.

Example: An assembly machine for cables processes high amount of copper per minute and you need only few of them per many furnaces. So its wise to use product modules thanks to argument B becouse this modules saves 20% of energy consumption of all precedents.

Another example: Solid fuel making works really slow. It processes one light oil into solid fuel per 3 sec only and you need a very high amount of chem plants (even with smart becons). So using the second way should be smart becouse light oil is quite cheap. I simply recommend something like this Its a huge plant, however, who says that size of this plant is more valuable than your solar panel plant? It is also very cheap if you include the fact that you need only level 2 modules.

Important note: A is not an opposite of B. Your decision should follow this logic:

A is true, B is false -> deffinetly second way (efficiency modules)

A is false, B is true -> deffinetly first way (productivity modules)

A is true, B is true or...

A is false, B is false -> You have to compare. If the argument A is more valid then argument B. And how much you really care about energy savings.

I think that most of examples is fit for productivity modules. Solid fuel making is wise to switch into efficiency. And extrction of raw ores and furnaces is speculative for me.

1) product modules + speed modules in beacons

2) efficiency modules

and no other way. One can use a combination 3 efficiency + 1 speed at assembly machine since you are limited by 20% in energy consumption.

I think that your whole factory should have some parts oriented to first way and some parts to the second. If you try to decide between them, you should follow this factors for each process

A) If the energy consumption is too high (in comparison with other processes), its argument for the second way (efficiency modules).

B) If the energy consumption of precedents processes is too high, its argument for the first way.

C) If there is some valuable and hardly getable source at precedents, its argument for the first way.

Example: An assembly machine for cables processes high amount of copper per minute and you need only few of them per many furnaces. So its wise to use product modules thanks to argument B becouse this modules saves 20% of energy consumption of all precedents.

Another example: Solid fuel making works really slow. It processes one light oil into solid fuel per 3 sec only and you need a very high amount of chem plants (even with smart becons). So using the second way should be smart becouse light oil is quite cheap. I simply recommend something like this Its a huge plant, however, who says that size of this plant is more valuable than your solar panel plant? It is also very cheap if you include the fact that you need only level 2 modules.

Important note: A is not an opposite of B. Your decision should follow this logic:

A is true, B is false -> deffinetly second way (efficiency modules)

A is false, B is true -> deffinetly first way (productivity modules)

A is true, B is true or...

A is false, B is false -> You have to compare. If the argument A is more valid then argument B. And how much you really care about energy savings.

I think that most of examples is fit for productivity modules. Solid fuel making is wise to switch into efficiency. And extrction of raw ores and furnaces is speculative for me.

Last edited by MBas on Thu Feb 09, 2017 5:30 pm, edited 1 time in total.

Re: Final (Maxed) Designs

From what I've seen, 4x productivity module + 2x speed module in 8 beacons/assembler nets the best energy/item ratio. The idle consumption though is pretty nuts.

My Mods: mods.factorio.com

Re: Final (Maxed) Designs

Obviously not in many cases. You can take a material consumption statistic of rocket parts for example.Optera wrote:From what I've seen, 4x productivity module + 2x speed module in 8 beacons/assembler nets the best energy/item ratio. The idle consumption though is pretty nuts.

https://wiki.factorio.com/Rocket_part

Base consumption

9,950 Coal

42,805.555 Water

43,527.778 Crude oil

85,285.5 Copper ore

101,535 Iron ore

Consumption with productivity modules boost

3,249 Coal

12,289 Crude oil

17,375 Copper ore

33,189 Iron ore

The highest saving is in copper ore. But its still "only" five times. Efficiency modules makes everything five times more economical. So using productivity modules everywhere is for case that you value raw resources and are too lazy for expands

Its nice to have some of your factory parts smaller. But some of them are comfortable for stacking into huge sizes and there is no reson why you should not do that against stacking your solar panel plant.

Re: Final (Maxed) Designs

Efficiency modules have no impact on "Final (Maxed) Designs," since it doesn't impact throughput. Whether an Assembler 3 has 4 efficiency modules or 0, the throughput will be the same. (I'm not arguing against their use. Just stating that their use has no impact regarding this thread).

Although arguable, but just adding speed modules, which does affect throughput, is not appropriate when considering the layout for "Final (Maxed) Designs" unless space needs to be provided for Beacons. I reason that using speed modules this way shows a lack of planning when a similar effect can be accomplished, for far cheaper, by providing the optimum number of production buildings.

However, I definitely see a place for productivity modules and "speed module in beacon" layouts in this thread.

Although arguable, but just adding speed modules, which does affect throughput, is not appropriate when considering the layout for "Final (Maxed) Designs" unless space needs to be provided for Beacons. I reason that using speed modules this way shows a lack of planning when a similar effect can be accomplished, for far cheaper, by providing the optimum number of production buildings.

However, I definitely see a place for productivity modules and "speed module in beacon" layouts in this thread.

Re: Final (Maxed) Designs

Ok. My apologize. However i dont find any about using modules in your "rules" at your very first post.DerivePi wrote:Efficiency modules have no impact on "Final (Maxed) Designs," since it doesn't impact throughput. Whether an Assembler 3 has 4 efficiency modules or 0, the throughput will be the same. (I'm not arguing against their use. Just stating that their use has no impact regarding this thread).

Although arguable, but just adding speed modules, which does affect throughput, is not appropriate when considering the layout for "Final (Maxed) Designs" unless space needs to be provided for Beacons. I reason that using speed modules this way shows a lack of planning when a similar effect can be accomplished, for far cheaper, by providing the optimum number of production buildings.

However, I definitely see a place for productivity modules and "speed module in beacon" layouts in this thread.

My point was that not each parts of factory is supposed to be filled with produtivity modules in final designs (yes, i am posting about finals). Some parts around oil proccessing is much better to switch into efficiency way and when there is more possibilites in the game, why we should constrain our approach into one model?

Re: Final (Maxed) Designs

The one criteria I've stated for this post is that a max design include at least one input or output that is maxed out (40 items on a blue belt or 60 units in a pipe). The solutions that fit that criteria can be myriad. I do ask that the solution also be worked through so that it doesn't waste space or resources as well, but I think that is intrinsic to most designs. If you want to show efficiency modules, that's fine. Its just that efficiency modules do not impact max design and a layout with efficiency modules is equivalent to one without as it regards to "max design."MBas wrote:when there is more possibilites in the game, why we should constrain our approach into one model?

I'm actually not much for using modules for most layouts and use them sparingly in my own games. However, if someone wants to plan for a layout using beacons in their end game, then I'd like to present that space efficient, worked out layout here. Maybe a 5 Chem plant layout to max out a blue belt with plastic instead of the 16 chem plants for a non-moduled/beaconed design. Just have to figure out how to insert out 8+ units of plastic out of the plant per second.

Re: Final (Maxed) Designs

Ok, i see the point. Anyway, if you are interested in plastic process with your criteria, see viewtopic.php?f=202&t=40886. I allready have a design with 4600 /minute output splitted into two express belts. Its about 38.33 per second for one belt. Its not perfect 40 but its close.DerivePi wrote:The one criteria I've stated for this post is that a max design include at least one input or output that is maxed out (40 items on a blue belt or 60 units in a pipe).MBas wrote:when there is more possibilites in the game, why we should constrain our approach into one model?

-

skillabstinenz

- Inserter

- Posts: 43

- Joined: Thu Aug 18, 2016 12:13 am

- Contact:

Re: Final (Maxed) Designs

It costs less energy to pick from the far belt side. Since coal is taken less than ore it should always be on the inside belt side.DerivePi wrote:Final Smelting Design

Schematic (forthcoming)

Picture

blueprint string

Similar like this: http://picpaste.com/pics/coal-55vv5nJZ.1486742710.png

But it's good to see, that someone uses all belts and not the blue belts/inserters everywhere crap I have to endure on YT.

- hansinator

- Fast Inserter

- Posts: 160

- Joined: Sat Sep 10, 2016 10:42 pm

- Contact:

Re: Final (Maxed) Designs

Here's a smelting from dragontamer5788 that someone else referenced in another thread, it is more compact:

Original thread here: viewtopic.php?f=8&t=30784&start=20#p194683dragontamer5788 wrote: 9x70 design. 630 tiles for fully compressed input and output per line. For a grand total of 1890 tiles if this design were to scale up to 3 output belts. (UNDER 2000 tiles!)

In the early game, you could accomplish the same with yellow-belts with 2x12 (24 total) steel furnaces (or 2x24 or 48 stone furnaces in the super early game) to fully saturate a yellow-belt's worth of iron.

Re: Final (Maxed) Designs

Seems wasteful to use blue belts all the way. On input as iron ore is used up the belts could become red and then yellow. On output they could start yellow and become red and then blue. Also why are any of the fast inserters needed?hansinator wrote:Here's a smelting from dragontamer5788 that someone else referenced in another thread, it is more compact:

Original thread here: viewtopic.php?f=8&t=30784&start=20#p194683dragontamer5788 wrote: 9x70 design. 630 tiles for fully compressed input and output per line. For a grand total of 1890 tiles if this design were to scale up to 3 output belts. (UNDER 2000 tiles!)

In the early game, you could accomplish the same with yellow-belts with 2x12 (24 total) steel furnaces (or 2x24 or 48 stone furnaces in the super early game) to fully saturate a yellow-belt's worth of iron.

I love the use of underground belts to compress the output though.

- hansinator

- Fast Inserter

- Posts: 160

- Joined: Sat Sep 10, 2016 10:42 pm

- Contact:

Re: Final (Maxed) Designs

I seriously have no idea why there are fast inserters, but I think they are not needed and that they are just there. However, the design is "maxed" in the sense that it outputs a full blue belt. Your are free to improve on inserters and belts to make it cheaper to constructmrvn wrote:Seems wasteful to use blue belts all the way. On input as iron ore is used up the belts could become red and then yellow. On output they could start yellow and become red and then blue. Also why are any of the fast inserters needed?hansinator wrote:Here's a smelting from dragontamer5788 that someone else referenced in another thread, it is more compact:

Original thread here: viewtopic.php?f=8&t=30784&start=20#p194683dragontamer5788 wrote: 9x70 design. 630 tiles for fully compressed input and output per line. For a grand total of 1890 tiles if this design were to scale up to 3 output belts. (UNDER 2000 tiles!)

In the early game, you could accomplish the same with yellow-belts with 2x12 (24 total) steel furnaces (or 2x24 or 48 stone furnaces in the super early game) to fully saturate a yellow-belt's worth of iron.

I love the use of underground belts to compress the output though.

Re: Final (Maxed) Designs

Does someone have the numbers for maxed out designs with modules?

For example what about electric furnaces with productivity modules?

Or is the cost of the modules so high that you will only recoup the investment when running the game for over a year?

Or what about designs that include their own power? Anyone calculated how many solar panels and accumulators to have for a maxed out electronic circuit plant?

For example what about electric furnaces with productivity modules?

Or is the cost of the modules so high that you will only recoup the investment when running the game for over a year?

Or what about designs that include their own power? Anyone calculated how many solar panels and accumulators to have for a maxed out electronic circuit plant?

Re: Final (Maxed) Designs

Science - Final Design

This is sized for 5 of each science per second. It is "max" due to the full belt of basic circuits required for producing the inserters for green science and the filter inserters for blue science. Other than the belt and inserter production, the other ingredients are from offsite. The top 2 row of assemblers are 2-belts, 2-inserters, 2-more inserters, 2-fast inserters and then 2-filter inserters. The next rows are 20 red science, then 24 green science, then 2 rows of 24 science centers, 2 rows of 24 blue science and then 5 purple assemblers.

Schematic

Picture

Blueprint

This is sized for 5 of each science per second. It is "max" due to the full belt of basic circuits required for producing the inserters for green science and the filter inserters for blue science. Other than the belt and inserter production, the other ingredients are from offsite. The top 2 row of assemblers are 2-belts, 2-inserters, 2-more inserters, 2-fast inserters and then 2-filter inserters. The next rows are 20 red science, then 24 green science, then 2 rows of 24 science centers, 2 rows of 24 blue science and then 5 purple assemblers.

Schematic

Picture

Blueprint

blueprint string

Last edited by DerivePi on Thu Feb 16, 2017 3:40 am, edited 1 time in total.

Re: Final (Maxed) Designs

Plastic - Final Design

This is the basic, non-beacon layout for plastic. Fairly simple. Like the smelting layout, I chose to use the two belts merging into one blue belt to avoid problems with packing a single belt with inserters. Still had to play some games with splitters to balance the side belts.

Schematic Picture (forthcoming)

Blueprint (forthcoming)

This is the basic, non-beacon layout for plastic. Fairly simple. Like the smelting layout, I chose to use the two belts merging into one blue belt to avoid problems with packing a single belt with inserters. Still had to play some games with splitters to balance the side belts.

Schematic Picture (forthcoming)

Blueprint (forthcoming)

Re: Final (Maxed) Designs

EDIT: Ignore this reply, my finished design is just below.

So it seems you have some further criteria in your head, based on your preferences for efficient use of resources including both raw materials and space (and perhaps a bit of aesthetics). But why does the iron going into a blue belt enter consideration, but not the coal used in your steam engines or the solar panels/accumulators you had to build to run your other machines? (to say nothing of the space these things take up). Not to mention the extra resources needed to defend your base with the mass quantities of pollution you put out using prod + speed beacons.

The only truly limited resource in factorio is time. Your time. You can use it to acquire any of the others. So if I decide I'm going to use up some extra space and create a massive, but low power, smelting station, how are you going to tell me it's not "maxed"?

This is definitely not a "maxed design" (in fact it's my first round of testing -- run off local mines so I need to set up trains before maxing). As such it only outputs 2 red belts currently. But I think it's fairly obvious where I'm going, because from here it's just repeated. Here: is my thought for a smelting design (healthy criticism welcome; I ask you do better than 'those modules suck' though). Not compacted yet (or measured), but the bigger problem than the smelting layout itself is bringing in enough ore without a 36 lane bus. Still working on how to do the drop off/pick up though.

is my thought for a smelting design (healthy criticism welcome; I ask you do better than 'those modules suck' though). Not compacted yet (or measured), but the bigger problem than the smelting layout itself is bringing in enough ore without a 36 lane bus. Still working on how to do the drop off/pick up though.

Uses just 90kw and produces 0.45 pollution per furnace. Not sure how this works out in comparison (math is next), but I would assume that I get more iron/kw and iron/pollution than your design. As MBas said, I think it's valid to maximize performance for all considerations. Otherwise I think you have to eliminate prod modules from this thread too; they only increase output per resource input, and actually hurt output per time.

Edit: I just figured out your reasoning as to why it 'doesn't affect throughput'. Not sure why I didn't follow in the first place. Still, once I scale this up I will have maxed input and output (though it won't be just one belt, so that might disqualify me as well). For my purposes, iron ore is now plentiful. Now I want to substantially increase iron production without substantially increasing the number of solar panels I need to place.

I'm not sure I follow your reasoning here. If the one criteria is a single maxed input or output, modules don't matter at all. Of course, you're saying that they don't change the units/s, but neither does the use of yellow and red belt instead of all blue. And that still leaves no room for comparison in the use of speed vs productivity, because both are capable of producing designs which max out a single input or output.DerivePi wrote:The one criteria I've stated for this post is that a max design include at least one input or output that is maxed out (40 items on a blue belt or 60 units in a pipe). The solutions that fit that criteria can be myriad. I do ask that the solution also be worked through so that it doesn't waste space or resources as well, but I think that is intrinsic to most designs. If you want to show efficiency modules, that's fine. Its just that efficiency modules do not impact max design and a layout with efficiency modules is equivalent to one without as it regards to "max design."MBas wrote:when there is more possibilites in the game, why we should constrain our approach into one model?

So it seems you have some further criteria in your head, based on your preferences for efficient use of resources including both raw materials and space (and perhaps a bit of aesthetics). But why does the iron going into a blue belt enter consideration, but not the coal used in your steam engines or the solar panels/accumulators you had to build to run your other machines? (to say nothing of the space these things take up). Not to mention the extra resources needed to defend your base with the mass quantities of pollution you put out using prod + speed beacons.

The only truly limited resource in factorio is time. Your time. You can use it to acquire any of the others. So if I decide I'm going to use up some extra space and create a massive, but low power, smelting station, how are you going to tell me it's not "maxed"?

This is definitely not a "maxed design" (in fact it's my first round of testing -- run off local mines so I need to set up trains before maxing). As such it only outputs 2 red belts currently. But I think it's fairly obvious where I'm going, because from here it's just repeated. Here:

is my thought for a smelting design (healthy criticism welcome; I ask you do better than 'those modules suck' though). Not compacted yet (or measured), but the bigger problem than the smelting layout itself is bringing in enough ore without a 36 lane bus. Still working on how to do the drop off/pick up though.

is my thought for a smelting design (healthy criticism welcome; I ask you do better than 'those modules suck' though). Not compacted yet (or measured), but the bigger problem than the smelting layout itself is bringing in enough ore without a 36 lane bus. Still working on how to do the drop off/pick up though. Uses just 90kw and produces 0.45 pollution per furnace. Not sure how this works out in comparison (math is next), but I would assume that I get more iron/kw and iron/pollution than your design. As MBas said, I think it's valid to maximize performance for all considerations. Otherwise I think you have to eliminate prod modules from this thread too; they only increase output per resource input, and actually hurt output per time.

Edit: I just figured out your reasoning as to why it 'doesn't affect throughput'. Not sure why I didn't follow in the first place. Still, once I scale this up I will have maxed input and output (though it won't be just one belt, so that might disqualify me as well). For my purposes, iron ore is now plentiful. Now I want to substantially increase iron production without substantially increasing the number of solar panels I need to place.

Last edited by TI-89 on Mon Feb 27, 2017 10:34 pm, edited 1 time in total.

Re: Final (Maxed) Designs

OK, so I adapted your design using electric furnaces with a side loading layout, optimized the spacing and came up with this for "maxed design." I will say its challenging to think of a situation where you'd want to side load the ore. Why not load it from the end so that ore comes from the left and plates leave to the right? With end loading, one smelter will stack nicely next to others. Under this layout you wind up with a chevron style stacking.TI-89 wrote:This is definitely not a "maxed design" (in fact it's my first round of testing -- run off local mines so I need to set up trains before maxing). As such it only outputs 2 red belts currently. But I think it's fairly obvious where I'm going, because from here it's just repeated. Here: is my thought for a smelting design (healthy criticism welcome; I ask you do better than 'those modules suck' though). Not compacted yet (or measured), but the bigger problem than the smelting layout itself is bringing in enough ore without a 36 lane bus. Still working on how to do the drop off/pick up though.

Re: Final (Maxed) Designs

Inane Nonsense - Read at Own Risk

Ok since I kinda took this thread off topic by posting an unmaxed design (using efficiency modules no less!

Re: Final (Maxed) Designs

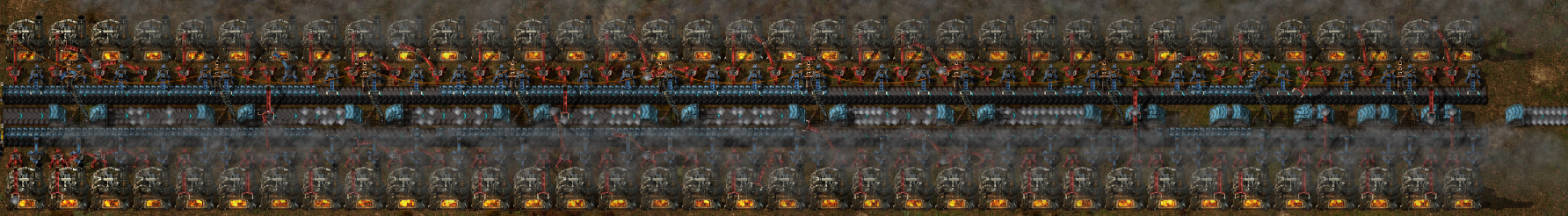

Steel Smelting in Electric Furnaces with Beacons

So I thought I'd have a go with beacons. This arrangement will take 167 iron plates and smelt them into 40 steel per second using 64 electric furnaces. Most of the furnaces have 8 beacons in range.

Schematic

So I thought I'd have a go with beacons. This arrangement will take 167 iron plates and smelt them into 40 steel per second using 64 electric furnaces. Most of the furnaces have 8 beacons in range.

Schematic