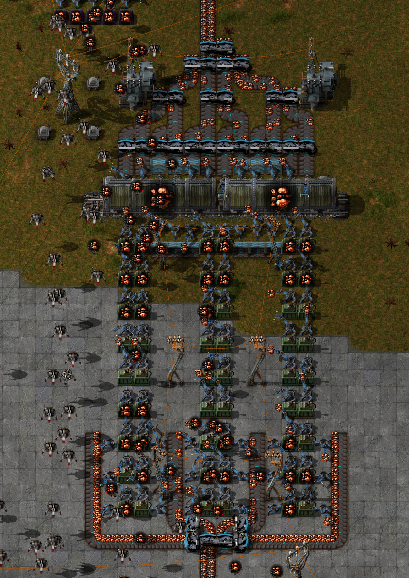

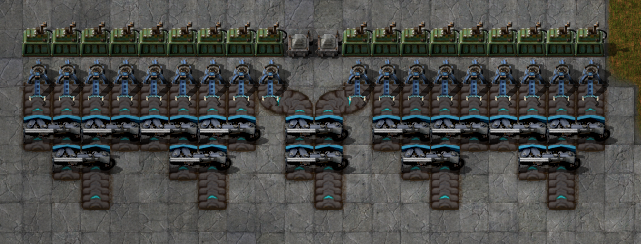

This is my original design:

But as you can see there's a few small problems with it.

As material enters inserter range at the bottom, the inner inserters will always receive priority over the outter ones resulting in a poorly balanced offload.

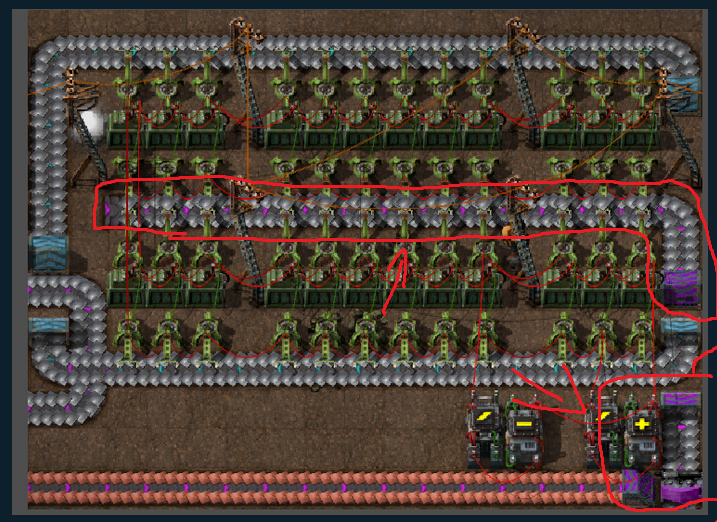

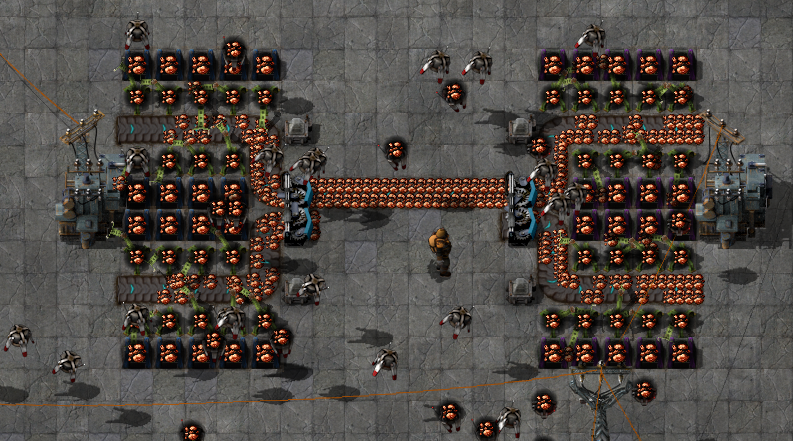

Based on tests and information from the wiki, it is confirmed that 9 blue inserters for both sides of the express belt will fill it to maximum capacity, with the 9th inserter on both sides operating at around 60% capacity.

In other words 18 total inserters.

Tested and confirmed that removing 1 then load balancing the 17th will not fill an express belt to max, you really need 18.

Visually, this is the optimal layout for a logistics-fed express belt loader/offloader:

Now onto the math problem.

How do we turn 2 into 3?

9/2 = 4.5

We can visually see this as the 4 whole numbers (1 per belt on each side) then the 0.5 belt in the middle in the following picture;

In other words, the middle belt only needs half (0.5) of what the 4 outter belts (1 per) need.

After some testing, it appears there is no difference with throughput when switching to smart inserters.

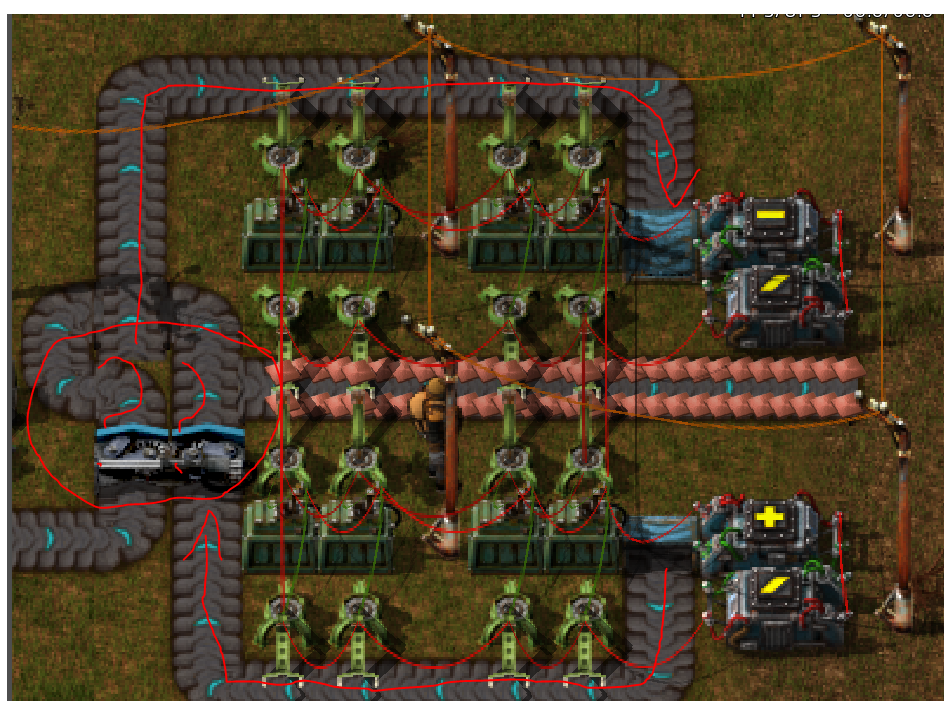

How do?

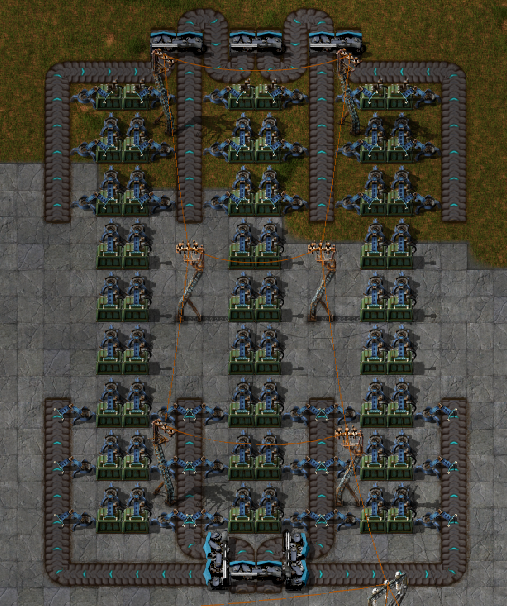

This is the best i've come up with so far, with the help of the inserter stack size bonus.

But even this has a problem of resources building up at the very last chest meaning it will not always output a max capacity express belt.

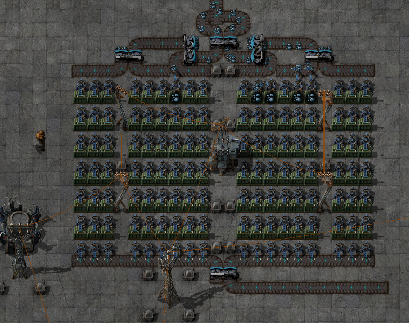

** SOLVED **

With some help from my friends, it was suggested to me to use a train as the offload point which solves any possible resource distribution problems from the previous image.

The following is the best load balanced express belt onload/offload storage facility that can possibly be made that doesn't have any distribution issues.