I like the rebalance to drillheads and toolheads. Much less expensive to run.YuokiTani wrote:next version will support a smelter, but of course a different way ... because vanilla-code-limitations ... but it counts the result.

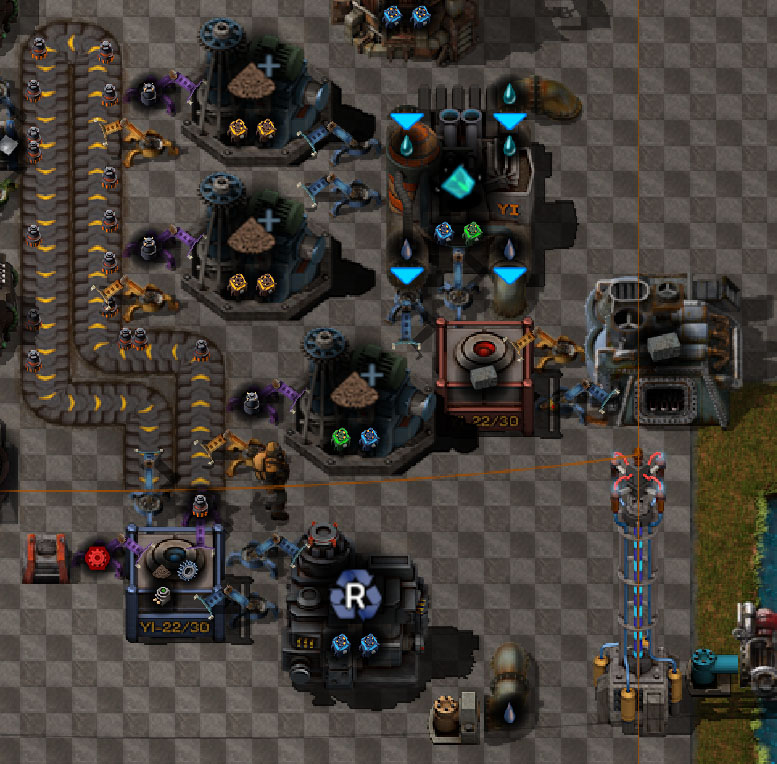

2 more simple examples of drillhead-repair with request-chestspicturesdrying water in place is better, you transport the end-products - but depends on how far.

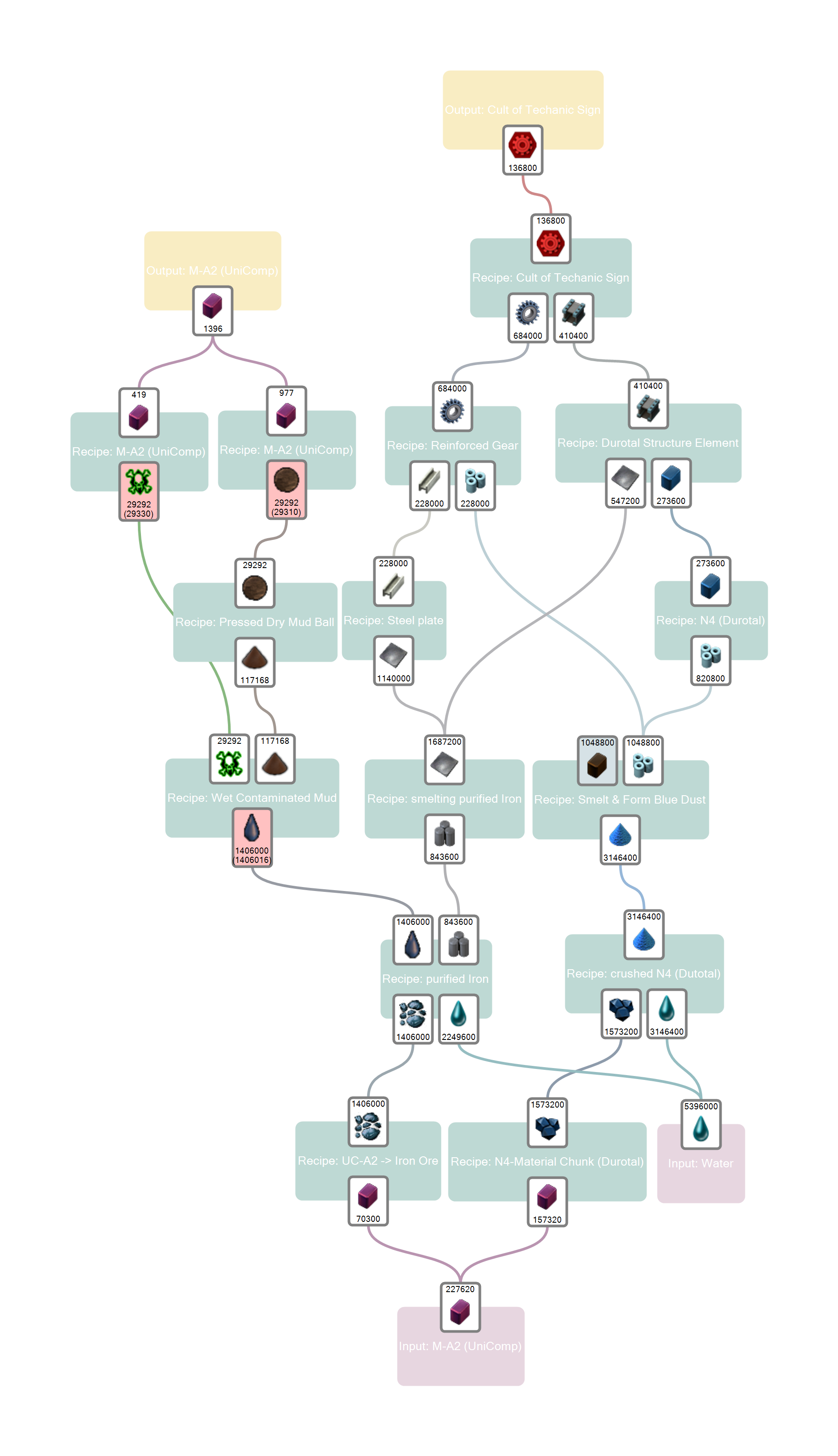

also end-products can transformed into unicomp.

I see good tradeoffs where I could run 4 dirt miners with drillheads with ~4 support machines or 32 drills without. The drillheads now only cost ~13% of the total unicomp output of a washing setup where before they cost more than the total output. Power and space savings I think make it interesting decision to pay recurring repair costs or recurring power/space costs from more drills.

How are you looking to tune the ore washing process? Should it be a net unicomp loss?

This may be intentional, but I think stone might be a hair too valuable in unicomp. I plan a ore washing setup for 5 blue belt of input (40 MC washers). It kicks off a ton of waste water and I compress that to mud and eventually it is just under 16 unicomp off the contaminated water to mud cycle. To run the ore washing with no modules I need 400 stone a minute = 20 unicomp. I think this is a good state it means I need stone/unicomp input from outside my ore washing. With the changes to drill heads I don't need the huge setup I had last version, but still a modest setup of ~7 master washers and 4 drill head diggers could supply all my stone or I could consume the unicomp and run maybe just 1-2 washers/diggers to fill the gap in stone and close the loop.

If I use yuoki productivity modules on the furnaces turning stone ore into brick I only need ~14 unicomp of stone. Since I generate 16 just washing ore I can run a small unicomp surplus with just my ore washing and a single unicomp -> stone ore -> stone brick furnace setup (~5 furnaces with 2 mantis modules each). No need to make dirt and wash it for stone + process the extra for unicomp. Still a pretty complex production and maintenance chain, but a little less interesting without having to provide stone or unicomp from outside the ore washing loop to sustain it.

I think it is very valuable for the extra output (5 lanes of ore becomes lanes of 8 plates), but the cost to run toolheads may need a tweak to make an interesting trade off/design decision on how you keep the gravy train running.

Drillbits run on duratol would toolheads run on nuatreel instead of stone brick? Looks like it would be the same 20 unicomp to make 200/m nuasteel pellets with basic crushing or 16.67 if you crush with toolheads. It would be a small surplus if you convert slag (2/m) to unicomp and do advanced processing and a small loss with basic processing (overall -2 unicomp a min). Nuatreel would be a little more interesting than the stone brick cycle, but the small surplus (1.21 unicomp/m) concerns me.

Duratols crushing/pressing ratios have it cost about 50% more in unicomp by the pellet stage... using 50% more nuasteel pellets in the toolhead repair recipes would shift it to a loss no matter what you do. I get -7 and -12 advanced crushing vs not. That is ~3-4 master washers washing for stone converting their outputs to unicomp -- if stone value also does not change washing for alien fragements + stone seems to be the best source of unicomp at the moment.

Sorry to ramble on!